Cement Industry

Reliable Bearings for Extreme Processing Conditions

Cement is one of the world's most important building materials and its production one of the most severe processing environments, and so demands outstanding performance. CHIN SING bearing sleeves provide the cement and related industries with the reliability, sustainability, and toughness required to withstand the critical processing factors of water, dust, and grit, extreme temperatures, vibration, and huge loads. Like other extreme processing and extraction industries, cement machinery must continuously operate under these challenging conditions.

Meeting the Cement Industry’s Demands

The cement industry has a need for high efficiency, increased productivity and throughput, reduced downtime due to equipment wear, and higher process quality. Bearings for the cement industry are designed to answer the requirements of the cement industry such as high temperatures, debris, heavy loads, and corrosive environments. The cement-making process has applications such as rotary kilns, clinker cooler, roller presses, vertical and horizontal mills, conveyors, etc.

Key Components for Improved Equipment Performance

As such our bearings are based on proprietary state-of-the-art technology, combined with the experience and knowledge from working with industry leaders. We have designed bearings to ensure your processes continue to run smoothly. CHIN SING bearings exceed the limits of conventional bearings in terms of long operating life and high limiting speed to give you the toughness you require.

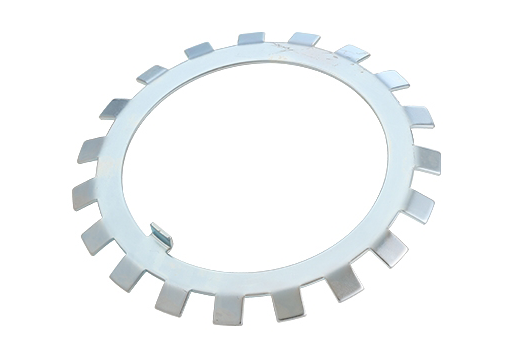

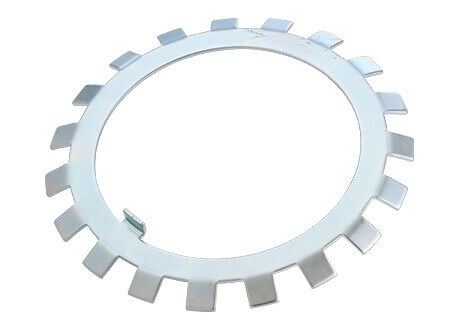

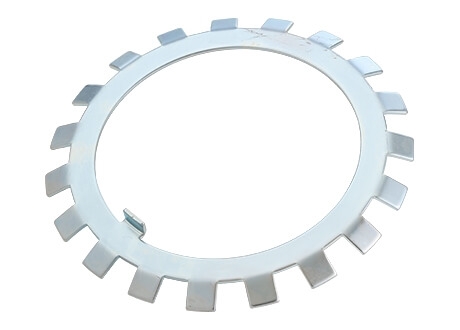

Components such as adaptor sleeve, bearing adaptor sleeves and lock plate play a key role in improving rotating equipment performance. Maximizing uptime and reducing maintenance costs for improved productivity at cement plants. Durability and reliability are of paramount importance where the failure of a single component can impact the entire cement manufacturing process. Our superior bearings offer high performance with robust design, helping you improve profitability and productivity. Meanwhile, our lubrication help automates the maintenance process, and reduce costs, while our experts can help you achieve this.

.png)

-index.jpg)

.jpg)

_防鬆螺帽-1.jpg)